Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

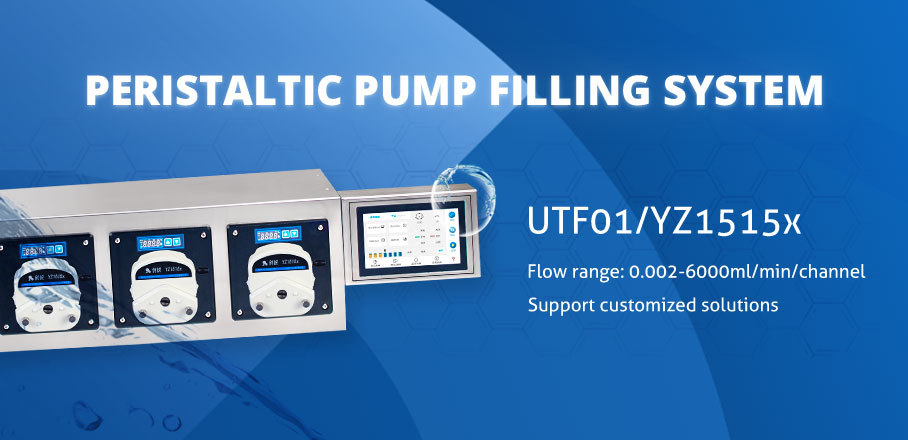

Model No.: UTF01

Jenama: CR

Flow Range: Max 2280ml/Min/Channel

Speed Range: 0.1-600rpm

Filling Accuracy: <±2%

Display Mode: 7 Inch / 10 Inches - Lcd Screen + 4- Led Display

Outlet Pressure: 0.1-0.12mpa

Motor: Stepper Motor

Calibration Method: Scale Adjustment, Volume Calibration

Customer Data Storage: 20 Groups

Pump Head Optional: YZ1515x

Model: UTF01

Pembungkusan: dengan karton

Produktiviti: 1000sets/month

Pengangkutan: Ocean,Land,Air,Express,Others

Tempat asal: China

Sokongan mengenai: 1000sets/month

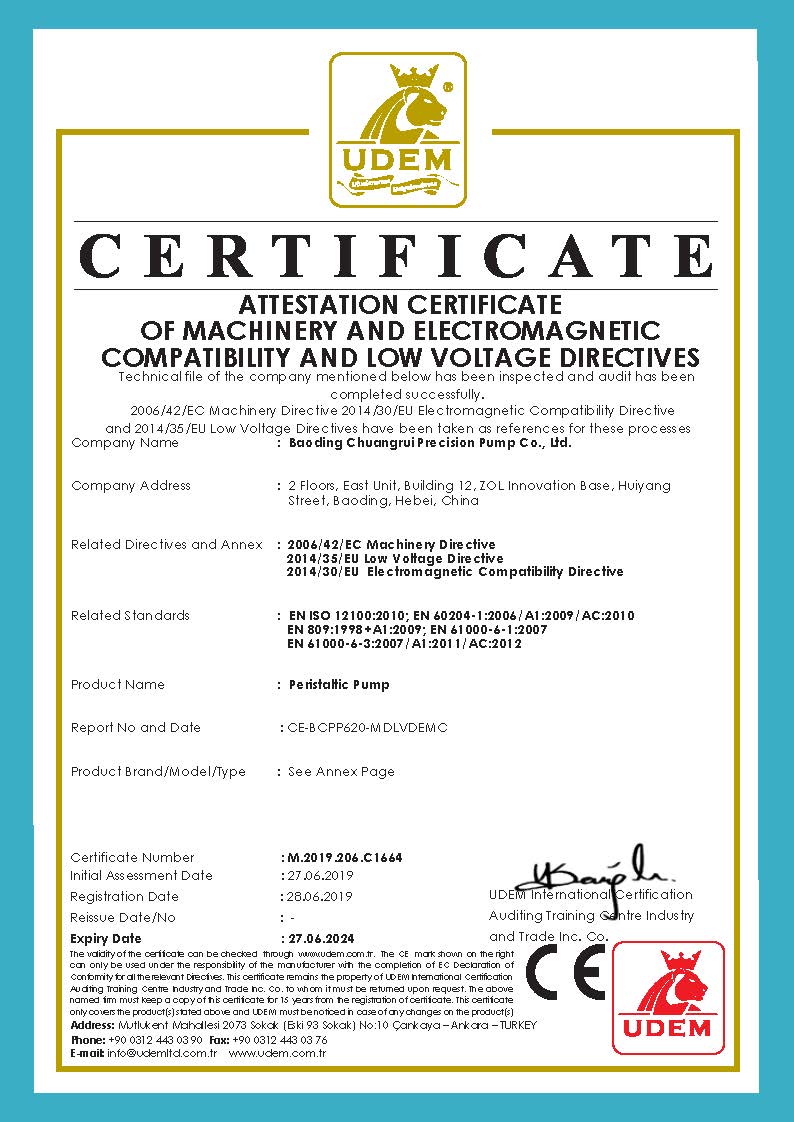

Sijil: CE ISO9001

Port: Beijing,Shanghai,Tianjin

Jenis bayaran: T/T,Paypal,Others

Incoterm: FOB,CIF,EXW,FCA

| Filling system | Main controller |

| Independent drive unit for easy mechanical matching | Large screen touch (7 inch / 10 inch) simple and intelligent |

| Independent key setting address /fine-tune flow | Manual touch screen /communication instruction, dual operation |

| Cascadable structure to 32 channels | Arbitrary control of each channel start /stop, forward / reverse |

| Online / offline flexible dual working mode | Arbitrar hannel simultaneousfilling or suck back |

| Support internal control / externalcontrol/communication control | Supports simultaneous suck back function of all channels (angle / delay) |

| Single channel No bottle No filling functiondrive | Support customer parameter scheme saving and retrievalmatching |

| Fine adjustment / calibration during filling processmatching | Provide scale adjustment / volume calibration function |

| Stable operation, strong anti-interference ability | Provide online filling volume adjustment function |

| Fault alarm to ensure safe production | Provide WiFi function (optional) |

| Stainless steel housing, sturdy, corrosion-resistant and easy to clean | RS485 bus communication interface, easy external control |

| Control Mode | Offline Mode | The filling operation is controlled by the main controller. |

| Online Mode | Through the external signal, the start-up of filling operation and the stop filling function are realized. When it is used together with the filling machine, the filling machine provides the start signal to complete the synchronization of liquid filling and bottle moving of the filling machine, and the filling machine provides the bottle missing signal to complete the function of bottle missing and stop filling. | |

|

Fill/ Recycle |

Filling Function | Filling is an auxiliary process of filling, which can quickly fill the liquid into the pipeline, consistent with the direction of filling work. |

| Recovery Function | Recovery is to quickly collect and recover the liquid in the pipeline from the outlet of the pipeline after filling, which is opposite to the direction of filling work. All channels can be carried out simultaneously or individually. | |

|

Back draw/ Reverse |

Back draw Function | Effectively avoid liquid drop during shutdown. Contains two processes of suck-back delay and reverse running. |

| Back draw Delay | The time between allocation completion and the start of the reversal. | |

| Reverse Operation | After the suck-back delay is over, the reverse rotation operation is started, and the reverse rotation angle is 0-1000 degrees. | |

|

Operation / Display |

Membrane button operation | The membrane address can be used to set the channel address and adjust the filling liquid volume online. |

| LED display function | LED display channel address or adjust liquid volume ratio online. | |

| Touch function | The touch screen operation controller controls the filling operation. | |

| PC operation | Host computer operation controller-adopts RS485 communication interface and supports ModbusRTU protocol. The host computer sends instructions to the filling unit controller to set controller parameters and control filling operations. | |

| Wireless connections | Optional WIFI module for wireless connection control. | |

|

Function Features |

Quantitative Filling Function | The filling system execution unit can be fitted with a variety of Fill Peristaltic Pump heads and adapted to a variety of hose sizes. The controller sets the filling volume for quantitative filling. |

| Lack of bottle filling stop function | Each channel has an independent bottle-out signal receiving terminal. When a bottle-out signal is received, the system will stop the filling operation of the channel. | |

| Liquid calibration function | It is used for accurate calibration of filling volume. Each channel can independently perform online scale adjustment, weighing calibration, and multiple weighing calibration. | |

| Channel enable function | You can set the enable or disable of each channel arbitrarily. The prohibited channels will not be filled. | |

| Customer data storage function | Filling series parameter settings can be saved as commonly used data, and the saved parameter scheme can be called as required. | |

| Password protection function | By setting a password, the system parameters set by the user are protected to prevent misoperation. |

Kategori produk : Pam peristaltic. > Mengisi pam

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.